Many makers use bending forms of one type or another to bend violin ribs, but a conventional bending iron is probably still employed by the majority of amateur makers. A bending strap is used in conjunction with the heated iron to do the work.

Groping along with little knowledge about how to proceed, over the past few years I have made rib bending straps out of brass, galvanized roof-flashing metal, aluminum, lead and 3 varieties of stainless steel.

The first strap I made was of stainless steel. It stained the ribs blue. Lesson learned: not all stainless steel is stainless for the maker’s purposes. The next strap was made of brass and it stained the ribs green. To my surprise the third strap made (galvanized roof flashing material) did not stain the ribs at all, nor did a strap made of aluminum. But the roof flashing material and the aluminum straps were thick, creased with each bend, and did not resume their pre-bending form readily and would have ultimately fractured. Another strap made from a different variety of stainless steel did not stain but was 0.020" thick, was not spring steel, and did not regain its pre-bending shape readily.

Frustrated, I corresponded with *Mr. Gerry Slavin who graciously supplied me with test strips of 0.003", 0.005" and 0.007" blue-tempered spring steel shim stock with which I made bending straps. Their flexibility and minimal creasing were very good but they stained the rib material blue. I thought that spring steel shim stock that was not blue in color might do the job without staining. Mr. Slavin then sent me some 0.005" low carbon steel shim stock. It worked smoothly as a bending material but it stained the wood blue also. When Mr. Slavin heard again from me, he sent me a sample of 0.005" shim stock of stainless steel. This material works fine and thus far has not stained the ribs. From this background of making rib-bending straps from several materials of different thicknesses and degrees of temper, I have concluded that:

The strap material must be of spring steel and stainless.

You have to try the strap material, even stainless steel, to determine whether it will stain the rib material.

0.005" is about the ideal thickness.

It should be of sufficient length that the operator can maneuver about a conventional rib bending iron without his hands being too close to the iron and so that the operator can change the direction from which he pulls against the iron. A strap with effective length of about 12 1/2" should prove adequate for violin and viola ribs.

Staining of the rib material can be prevented by wrapping the rib to be bent in a piece of paper towel material.

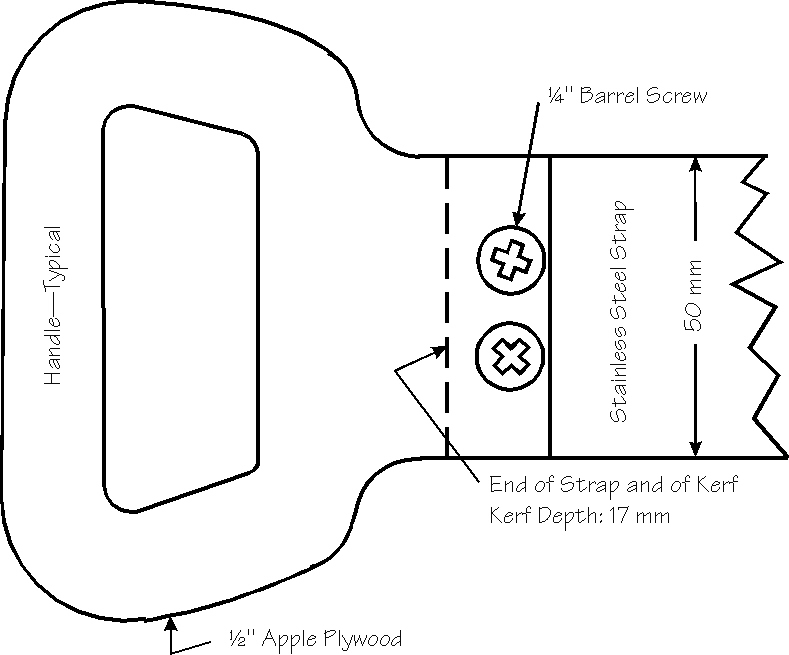

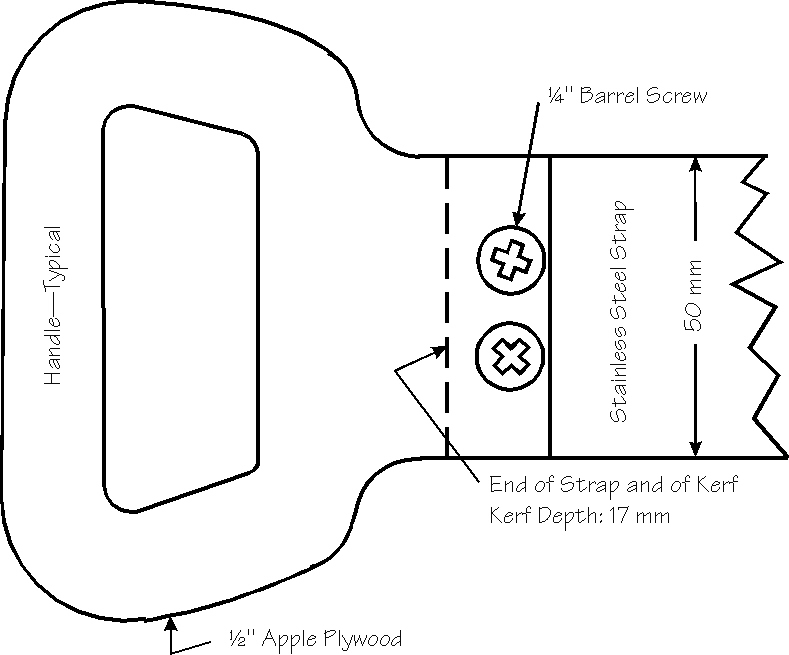

The evolving rib bending strap is 50.0 mm wide. Its overall length is 340 mm. The length of the strap between the inner ends of the “D” handles is 308 mm. The drawing shows the dimensions of the 1/2" Apple Plywood handles. 1/4" Barrel screws are used to hold the strap in the kerfed handles. The kerf was cut with a dovetail saw with a very thin blade. 1/4" holes are drilled through the handles, see sketch, to receive the Barrel screws. When the strap is drilled, the bit passes through the holes in the handle made for the Barrel screws and on through the strap. To do the strap drilling, it is inserted into the handle to the full depth of the kerf. A wooden hole-drilling fixture is used to align the strap perpendicular to the “pull” axis of the handles. The fixture is a piece of 1/2" plywood about 10" long with a 1/4" wide strip of wood glued to either edge. The strips are separated by a hair more than the width of the strap. The strap end of the handle rests in one end of the fixture and the strap is introduced to its full depth in the kerfed handle. The fixture helps resist any tendency of the strap to wander while its holes are being drilled. After one hole has been drilled in the strap, the male part of a Barrel screw is pressed into the handle and through the hole in the strap—further stabilizing the position of the strap. The screws are tightened such that the wood on either side of the kerfed handle compresses the strap forcefully.

It takes a little rib bending experience for a beginning maker to realize that, in addition to having the bending iron at the correct temperature, he must use considerable pressure and force on the bending strap as he bends the ribs. The strap must be kept completely flat against the rib and the strap must be perpendicular to the long axis of the bending iron.

*Shop-Aid Division, the N.E. Slavin Co., 50 Holton St., Woburn, MA 01801.

All Bulletin articles are copyrighted ©1997 by the Southern California Association of Violin Makers. Contact Bulletin editor John Gilson, at the address given on our home page, for permission to reproduce Bulletin material.